Bio-Microbics, Inc.

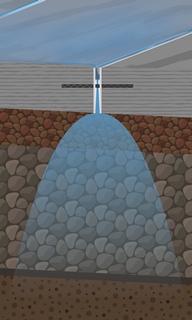

The d-Rain Joint Rainwater Filtration System

The d-Rain Joint is a simple, low-cost, and robust onsite storm water management alternative compared to other permeable, pervious surface options and can be used wherever a permeable, pervious driveway, parking lot, street or walkway is needed.

World Water Works, Inc.'s IDEAL MBBR™ Moving Bed Biofilm Reactors upgrade existing industrial wastewater treatment facilities for overloaded, non-performing, and/or undersized systems. The product can enhance existing performance and increase capacity of existing treatment plants by being installed in a small footprint reactor(s) upstream of the existing biological system. The IDEAL MBBR™ acts as a roughing reactor, unloading the existing system by 60-80%. The plant upgrade can be achieved with no disruption in facility manufacturing or wastewater system performance. World Water Works offers a special PAYS™ program that allows this upgrade to be paid overtime.

GE Water

Reduces energy consumption and increases MBR technology

GE’s New LEAPprimary technology reduces the energy consumption and increases the reliability of MBR technology while enabling maximum energy generation from wastewater.

Remote Monitoring/Control of Fluid Bed Dryers, Dewaterers

Process equipment manufacturer The Witte Co. has unveiled remote monitoring and control on its line of vibrating fluid bed dryers, coolers, dewaterers, pellet classifiers, conveyors, and other equipment. Controlled remotely with a dedicated PLC HMI, the remote desktop capability allows process engineers to start and stop batch and continuous operations, adjust their parameters, and check process conditions such as air temperature, airstream velocity, and retention time in real time while away from the processing line. This is ideal for water/wastewater, food, beverage, chemical, pharmaceutical, plastics, and other processors with multiple facilities worldwide and/or those operating in controlled environments.

Electro-Chemical Devices, Inc.

Seawater Dechlorination Analyzer

The DCA-23 analyzer is ideal for LNG terminals, electric power plants, and municipal water desalination plants.

World Water Works, Inc.

DEMON Nitrogen Removal Treatment System

The DEMON Nitrogen Removal Treatment System helps achieve energy self-sufficiency, reduces costs, and optimizes footprint.

Electro-Chemical Devices, Inc.

T80 Universal Transmitter

The Universal Transmitter delivers several analytical measurements and is ideal for biotech and pharmaceutical, chemical, food and beverage, wastewater, drinking water, oil and gas, power generation, and semiconductors.

EleVader™

With the release of the ASME A17.1-2007/CSA B44 Safety Code for Elevators & Escalators, a new era has begun for elevator safety codes.