How LEDs Will Change Water Purification

LEDs have been a defining factor in many technological innovations, and water treatment is no exception. Although mercury lamp accidents are rare when lamps are installed correctly, the benefits of UV-C LEDs have begun to outweigh the need to stay with the status quo.

- By Mitch Hansen

- Apr 28, 2016

Ultraviolet (UV) light has been naturally purifying water for centuries. With clear skies, our sun can inactivate water-based pathogens in six hours minimum. Cloudy skies or unclear water causes imperfect conditions. These conditions allow for bacteria to grow and make natural water sources unsafe to use. Fortunately, we have developed several types of water disinfection, ranging from chemicals to UV lamps. Although these are all beneficial to human health, some are more environmentally beneficial than others.

The Need for Change

Advancements in chemistry and technology have resulted in multiple effective methods to purify water. Chemicals, such as chlorine, were the first widely used disinfection method and in many cases remain the primary means of purification. Chemical treatments dissolve pathogen cells entirely and, until ultraviolet (UV) treatment, were the best available option. However, there are downsides to using chemicals in drinking water. They can be toxic to aquatic life, create harmful byproducts, and are not effective against all pathogens (such as Cryptosporidium) . The chemicals used for disinfection are also highly corrosive and can cause safety and environmental risks during transportation and storage. (NSFC, National Small Flows Clearinghouse)

Although UV disinfection is considered safer than chemical use, all conventional UV lamps typically contain 20-200 milligrams of mercury and are susceptible to breakage during transportation, handling, and operation. Conventional UV lamps hold their mercury either in a liquid form (more common in medium pressure lamps) or in an amalgam (more common in low pressure, high output lamps). Accidents and improper procedures increase the risk of exposure.

The United Nations Environmental Programme (UNEP) initiated the Minamata Convention on Mercury to protect human health and the environment from anthropogenic emissions and releases of mercury. The UNEP has set the goal for mercury to be phased out of production by the year 2020. In 2013, organizations and governments were asked to discourage the use of mercury starting immediately, and 127 countries signed to ratify the removal of all mercury by the year 2020. While it is unclear whether UV lamps for water disinfection will receive an exemption from this regulation, it is clear that alternatives should be actively considered.

UV-C LEDs for Water Disinfection

LEDs have been at the forefront of lighting innovations since their inception – smartphones would not exist without them. They allow for longer lives, fast on/off times, and low power consumption. LEDs have been developed over the last few decades, with UV LEDs being the latest innovation. Each advancement in the light spectrum offers new possibilities for LEDs.

Unlike conventional UV lamps, LEDs do not use mercury, meaning there is no risk of contaminating the water if the lamp is improperly installed or broken. Conventional lamps also require 5-10 minutes to warm up to peak disinfection temperatures, while UV-C LEDs have a start time of a few nanoseconds and have no on/off limitations, allowing for instantaneous disinfection and flexible running times. Mercury lamps have a limited life cycle of roughly one year and require special disposal, whereas LED lamps can have replacement intervals of over 10 years.

All LEDs are known for their low energy consumption, and the same is true for UV-C LEDs when used in a quality disinfection system. Conventional mercury lamps require between 110 to 240 volts to operate, while LEDs require low voltage DC, meaning disinfection powered with a small solar panel or battery is feasible.

The ideal wavelength to inactivate most bacterium is between 260-270 nm, however, it depends on the specific bacteria being targeted. Mercury lamps have two options: low pressure, which emit 254 nm; and medium pressure, which emit wavelengths between 200-300 nm. UV-C LEDs have selectable wavelengths allowing power to be targeted at the most efficient disinfection wavelength, not misaligned as with low pressure lamps or wasted as with medium pressure lamps.

The Future of Water Purification

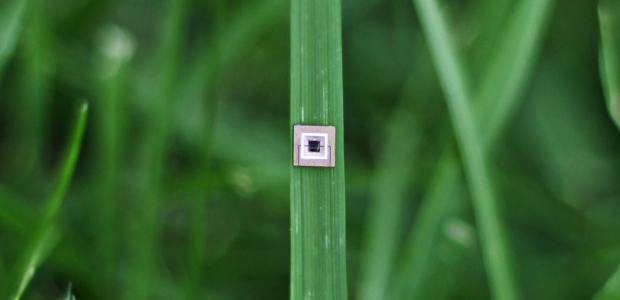

LED technology allows UV water treatment to be used in applications previously unavailable to conventional mercury lamps. For example, remote communities can easily purify water with solar power options, and mobile uses are now available due to the ruggedness and small size of the UV-C LED devices. Applied at the point of use, additional safety can be provided to water in hospitals and research facilities without the need for storage tanks. UV-C LED technology is not just theoretical or in a concept stage; the BIOWYSE Project is currently working on a device that will implement UV-C LEDs to disinfect water onboard the International Space Station. UV-C LED devices are currently available and ready to change the disinfection market.

LEDs have been a defining factor in many technological innovations, and water treatment is no exception. Although mercury lamp accidents are rare when lamps are installed correctly, the benefits of UV-C LEDs have begun to outweigh the need to stay with the status quo. Conventional ultraviolet treatment technology provided the world with an alternative to chemical water treatment. Now, with advancements in LEDs, we have come to the next stage of water purification.

About the Author

Mitch Hansen is an E-Marketing Specialist with AquiSense Technologies. AquiSense Technologies is a water disinfection manufacture located in Florence, Ky. AquiSense (www.aquisense.com) manufactures the world's first UV-C LED disinfection devices, providing new alternatives for clean water, air, and surfaces.