Good Compost Neighbor Uses Robust Odor Control

“That which we call a rose by any other name would smell as sweet.”

-Shakespeare

Long before Shakespeare, we formed relationships with odor. When odor evokes a positive response, it might be called a “scent,” “aroma” or “fragrance.” If our noses twitch or itch, the smell quickly becomes classified as a “stench” or “stink.” Sweet, fruity, musty, rancid ─ however you describe them, odors evoke emotions.

At our composting facilities in North America, which recycle hundreds of thousands of tons of organic waste into high quality compost, we know that keeping "the community nose" happy is integral to our success. Robust odor control technologies and management systems enable our company to "stay sweet" with our neighbors.

Preventing odors is easier than treating odors, so we take care to proactively manage incoming feedstock. For example, we do not store or stockpile any waste that is more likely to emit nuisance odors, like food waste, which decomposes quickly. Instead, our operators inspect the load, adjust for ideal composting conditions – density, moisture, carbon and porosity – and promptly place the mixed feedstock into a composting cell. Also, we do not pre-grind or shred the feedstock, thus minimizing the time spent exposed to the elements and awaiting attention. In short, we avoid and prevent odors by processing top-quality feedstock quickly and with minimal handling.

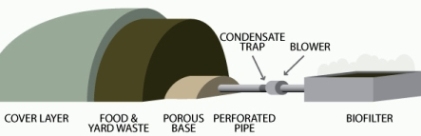

We have designed our composting cells to take advantage of basic geometry principles to contain odors. Consider the elements of our proprietary unturned covered aerated static pile (CASP) technology:

- The pile construction has a small footprint and a height greater than 25 feet. By minimizing the surface area, we shrink the odor-release surface area.

- We do not turn our compost cells, again reducing the opportunity for odors to be released into the air.

- We use an organic pile cover made of wood ash, compost, or bark, which acts as a natural biofilter for any stray odors escaping out the top of the pile.

- CASP’s negative airflow system pulls air through the compost cells and out through a biofilter (see biofilter description below). This allows us to capture and treat malodorous air before it is released to the atmosphere.

Life inside the pile

Imagine, for a moment, life inside a compost cell. We provide an energy source (carbon), a protein source (amino acids and nitrogen), air flow (oxygen), and 40 to 60 percent moisture content (water) and then let millions of bacteria, fungi, and higher life forms like nematodes go to work. As these microorganisms process the organic materials, they create volatile organic compounds (VOCs) and odors (e.g. sulfides, amines, fatty acids, etc.). Now, imagine life inside the compost cell with a nice tropical breeze sweeping down through the pile. This tropical breeze, also known as our negative airflow system, carries VOCs and odor molecules down to and through a series of perforated pipes. At the end of the pipes the air is pushed out through a biofilter.

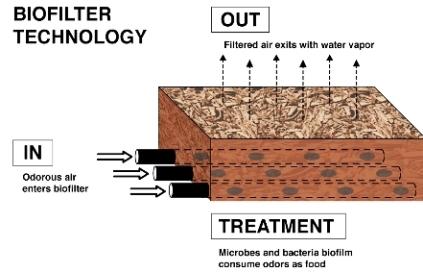

Biofilters eat odors and VOCs. On the surface, our biofilter technology looks like a benign pile of wood chips and bark (biofilter media). Upon closer inspection, you can see that the wood chips are coated with a slimy surface or “biofilm,” a microbial community that has adhered to the surfaces of the wood chips. As warm, moist air from the compost cell passes up through the biofilter, millions of microbes and fungi consume the odor molecules and VOCs as food. By the time the air flow reaches the top surface of the biofilter, the odors and VOCs have been converted into new biofilm, carbon dioxide and water vapor. We engineer our biofilter so that nature can do the heavy lifting of odor control. To ensure the biofilter works at the highest level, we periodically remove the biofilter media and replace it with fresh wood chips and bark. The best part is that the old wood chips get composted to make room for the new.

In addition to CASP and biofilter technologies, we employ various chemical and physical approaches to keep smells in check. These measures provide a back-up to our primary system. For example, at one of our facilities we use a neutralizer that attaches to odor molecules and modifies them mid-flight. The results are spectacular and immediate. However, chemical treatment is costly and only effective under certain conditions so we use it in measured doses. Another whimsical trick up our sleeve is to power up our spare DC-3 airplane propeller. The spinning blades blow potentially offensive air away from the neighbors and sufficiently mix the local atmosphere to reduce any residual odor.

We also track odors with our neighborhood sniffer, a local employee who follows the wind direction, heads downwind, and completes multiple transects through the community. The sniffer evaluates the smell using five olfactory benchmarks: intensity (e.g. strength ranging from no odor to overpowering), hedonic tone (e.g. pleasantness of the odor); character (e.g. fishy, grassy, minty, sweaty, etc); frequency (e.g. how often one is exposed to this odor); and duration (e.g. length of exposure). Odors are flighty things that change course and character over distance. By recording and tracking our material-handling activities, wind direction and odor characteristics, we identify patterns and are able to immediately respond to concerns whether they are real or perceived as real, and where the odor may have originated.

If Shakespeare were alive today, he would delight in describing our composting process. In honor of our odor control technologies and best management practices, I propose the following rhyme:

We manage our scents

Using prevention and common sense

Advanced odor control technologies

Use microbial ecologies!

Our role in the community

We do with integrity

Turning organic waste into soil

So our communities stay loyal.

About the Author

Meredith Sorensen is outreach manager at Harvest Power. The company provides technologies, project development, and product marketing capabilities to extract the maximum value from organic waste through the production of renewable energy in combination with high-quality compost-based soil and mulch products.