Case Study: Via Light Gas Station Bioremediation

- By James Lynn, Thomas Nail, Fabio Leandor

- Mar 18, 2010

Site plan. Click to enlarge.

When the new property owner purchased the gas station at Coronel Francisco Soares St., in Nova Iguaçu, Rio de Janeiro, in 2007, he unknowingly bought its environmental liabilities, too.

The typical fuel station supplies gasoline, diesel, ethanol, and natural gas to its customers. It had been revitalized in 2002, but that work did not address the property's tanks, fuel spills, underground soils, or groundwater. The new owner hired Consultoria Saneamento e Meio Ambiente Ltda. (CSM) to remediate contamination issues at the site.

CSM cleaned and degassed the underground tanks and installed a pump-and-treat system, but the technology was not lowering the benzene, toluene, ethylbenzene, and xylene (BTEX) levels to the State Environmental Institute of Brazil (INEA) standards for soil and groundwater. These standards (listed in the table) are equal to or more stringent than U.S. maximum contaminant levels in groundwater. In soil, the Brazilian standards are equal or more stringent than U.S. standards, which vary by state.

In June of 2008, CSM and the new property owner asked Grön Environmental for assistance. The new cleanup team shut down the pump-and-treat system and activated the S-200 bioremediation process, which was patented by James Lynn in 2001. Gron is the representative and distributor of the S-200 OilGone products in Brazil. The firm used existing wells and added a few more well points to inject S-200 into both the soil and groundwater. Grön uses the process developed in Spain with adaptations for its sites.

Brazilian Contamination Standards

| Contaminant |

In Groundwater |

In Soil |

| |

μg/L |

mg/Kg |

| Benzene |

5 |

1 |

| Toluene |

170 |

130 |

| Ethyl Benzene |

200 |

50 |

| Xylene |

300 |

25 |

The S-200 process is a bioremediation accelerator that binds with hydrocarbon pollution; it exponentially increases the population of hydrocarbon-degrading indigenous bacteria which, in turn, eliminate the hydrocarbon pollution.

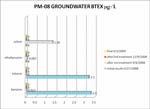

Groundwater BTEX chart. Click to enlarge.

This process was fully tested by the Spanish government and universities during the Prestige tanker spill off the Galatian coast of Spain in late 2002 through 2003. It is the improved second generation version of the bioremediation process used to clean 70 miles of coastline impacted by the Exxon Valdez tanker incident.

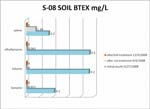

Three months after startup at the Nova Iguaçu gas station, the team took soil and groundwater samples, which showed reduced BTEX levels. Within six months, the results were below INEA compliance levels. In April 2009, new sampling and analysis confirmed completion of work at the site.

Soil BTEX chart. Click to enlarge.

S-200 is on the U.S. Environmental Protection Agency’s National Contingency Plan (NCP) Product Schedule. This listing does not mean that EPA approves, recommends, licenses, certifies, or authorizes the use of S-200 on an oil discharge. This listing means only that data have been submitted to EPA as required by subpart J of the NCP, Section 300.915. The data submitted exceed the testing criteria for the bioremediation effectiveness test and therefore qualifies S-200 to be listed on the product schedule.

The S-200 process, which costs about US$50,000 for one year of groundwater cleanup, can save significant amounts of money when compared to pump and treat, soil vapor extraction, and chemical oxidant technologies. The quick turnaround also allows for a faster property sale without deed restrictions or other legal hurdles.

About the Authors

James Lynn is president and chief executive officer

of International Environmental Products.

Thomas Nail is partner at Grön Environmental, Rio de Janeiro, Brazil.

Fabio Leandor is senior project manager at Grön Environmental.