Bio-Microbics, Inc.

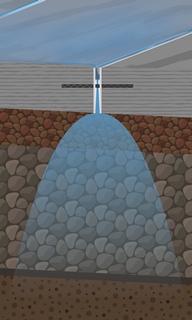

The d-Rain Joint Rainwater Filtration System

The d-Rain Joint is a simple, low-cost, and robust onsite storm water management alternative compared to other permeable, pervious surface options and can be used wherever a permeable, pervious driveway, parking lot, street or walkway is needed.

Koch Membrane Systems Inc.

PURON MP HOLLOW FIBER ULTRAFILTRATION PRODUCT

Koch Membrane offers a high-solids water treatment in an advanced cartridge design.

Electro-Chemical Devices, Inc.

DO90 Dissolved Oxygen Sensor

Engineers responsible for maintaining boiler operations will find the Model DO90 Trace DO2 Sensor from Electro-Chemical Devices (ECD) is designed for the continuous and highly accurate measurement of trace levels of dissolved oxygen, helping to maintain oxygen-free boiler feed water and reducing corrosion.

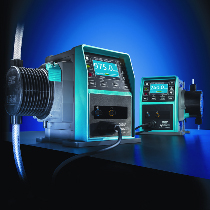

Watson-Marlow Pumps Group

Qdos 60 Metering Pump

Watson-Marlow Pumps’ Qdos 60 peristaltic metering pump is designed to reduce chemical metering costs compared to conventional solenoid or stepper-driven diaphragm metering pumps.

Koch Membrane Systems Inc.

MegaPure Hollow Fiber Ultrafiltration

Koch Membrane Systems, Inc. (KMS), world-class developer and manufacturer of innovative membranes and membrane filtration systems, announces its MegaPure hollow fiber product line. The product line is designed for high-solids water and wastewater applications, including surface water treatment, high total organic carbon (TOC) water treatment, reverse osmosis (RO) pretreatment, and tertiary wastewater treatment.

Fluid Components International

ST102A Air/Gas Thermal Mass Flow Meter

The new ST102A Air/Gas Thermal Mass Flow Meter features an advanced dual-element averaging system, improving installation repeatability and accuracy for larger diameter pipes and ducts.

World Water Works, Inc.'s IDEAL MBBR™ Moving Bed Biofilm Reactors upgrade existing industrial wastewater treatment facilities for overloaded, non-performing, and/or undersized systems. The product can enhance existing performance and increase capacity of existing treatment plants by being installed in a small footprint reactor(s) upstream of the existing biological system. The IDEAL MBBR™ acts as a roughing reactor, unloading the existing system by 60-80%. The plant upgrade can be achieved with no disruption in facility manufacturing or wastewater system performance. World Water Works offers a special PAYS™ program that allows this upgrade to be paid overtime.

Wilden Pump and Engineering Co.

Pro-Flo Shift

The Wilden Pro-Flo SHIFT represents a breakthrough in energy efficiency within the AODD pump category. Due to its design, the patent-pending Pro-Flo SHIFT Air Distribution System (ADS) allows Wilden AODD pumps to achieve up to a 60% savings in air consumption over all competitive AODD pump technologies.

KROHNE IFC 050 Electromagnetic Signal Converter

Reliable measurement of water flow is critical today and will be even more so in the future as water resources become rare. The new IFC 050 electromagnetic signal converter is the best long-term choice for measuring volumetric flow and can be used in several applications and many industries. Not only it is perfect for any kind of wastewater treatment metering tasks, it is also suited for water distribution networks, irrigation installation, water abstraction, and CIP cleaning stations.

Sensorex

Drop-in Replacement for Strantrol pH and ORP Probes

Sensorex’s S420 series probes offer an alternative to Strantrol pH and ORP probes used in swimming pool, industrial, municipal and potable water applications.

GE Water

Reduces energy consumption and increases MBR technology

GE’s New LEAPprimary technology reduces the energy consumption and increases the reliability of MBR technology while enabling maximum energy generation from wastewater.