Peer-to-Peer Wireless: A Game Changer for Confined Space Monitoring

New advances in gas detection equipment take real-world scenarios to heart and ensure everyone working around confined spaces will know where and why instruments are alarming.

- By Liz Keblusek

- Oct 20, 2016

You've probably heard the same confined space story too many times. A confined space entrant is performing routine work and becomes unresponsive. The attendant responsible for monitoring the work enters the confined space to check on the entrant and is overcome by deadly gas. It's a tragic story of trying to help a co-worker based on gut reaction rather than proper safety protocols. According to OSHA, would-be rescuers make up 60 percent of confined space fatalities.

Unfortunately, it's common for workers serving in the attendant role or "hole watch" to be inexperienced, untrained, or easily distracted by the numerous demands of a work site. Distractions can come in the form of radio calls, paperwork, talking to co-workers, or even while monitoring multiple confined spaces at one time. These distractions are rampant and increase the need for safety equipment that reduces the likelihood of human error.

Properly training all workers before they work in or around confined spaces is a must but, in reality, not every job is performed under ideal conditions or with enough information about gas hazards. New advances in gas detection equipment take these tragic real-world scenarios to heart and incorporate better communication technology to ensure everyone working around confined spaces will not only hear and see gas alarms, but also know where and why instruments are alarming. These new technologies aim to reduce would-be rescuer fatalities and accidents due to false evacuations. They also facilitate faster emergency response from trained peers in the field, rather than relying on help from a central controller many miles away. While it's common for workers to perform atmospheric testing in confined spaces with handheld portable instruments, area monitors with peer-to-peer wireless capability can improve efficiency and safety of confined space operations, particularly those calling for extended, continuous monitoring.

What is Peer-to-Peer Wireless?

Peer-to-peer wireless is a communication system that shares information between gas monitors, rather than sending alarm data to a central controller in another location. Area monitors in a peer-to-peer network do not require any infrastructure, IT setup, or a central host to operate. The focus of a peer network is to improve worker safety by being able to instantly deploy and share real-time alarms and gas readings between monitors. Workers are therefore instantly aware of gas hazards on the job site and are empowered to keep watch over one another during dangerous jobs such as confined space entries.

Where Area Monitors with Peer-to-Peer Wireless Win

Monitoring Multiple Confined Spaces:

According to OSHA regulations, 1910.146(d)(6), "Attendants may be assigned to monitor more than one permit space provided the duties described in paragraph (i) of this section can be effectively performed for each permit space that is monitored. Likewise, attendants may be stationed at any location outside the permit space to be monitored as long as the duties described in paragraph (i) of this section can be effectively performed for each permit space that is monitored."

While OSHA's rule says that watching multiple confined spaces at one time is acceptable, choosing the right gas detection tool is imperative.

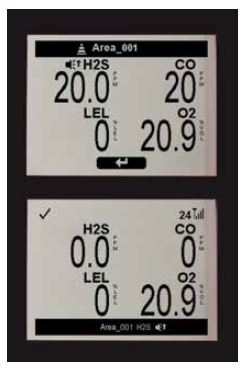

Area monitors that offer a large display, clear alarms, and long run times can exceed regulatory requirements, while adding wireless communication can increase the effectiveness and efficiency of safety programs. For example, if area monitors are placed outside confined spaces with tubing to draw samples from inside the space or are placed inside the confined space, they can relay the gas readings to other connected instruments. That allows the attendant the flexibility to monitor what’s happening from any other connected instrument. If one instrument goes into alarm, all connected units will go into alarm. The attendant will know exactly where the problem is because it’s visible on the instrument display. For example, the images to the left show the readings for two area monitors. The top monitor, within the confined space, is in alarm because of high H2S levels. The bottom monitor, which is placed near the attendant, shows a peer alarm indicating that there is high H2S in Area_001.

Area monitors that offer a large display, clear alarms, and long run times can exceed regulatory requirements, while adding wireless communication can increase the effectiveness and efficiency of safety programs. For example, if area monitors are placed outside confined spaces with tubing to draw samples from inside the space or are placed inside the confined space, they can relay the gas readings to other connected instruments. That allows the attendant the flexibility to monitor what’s happening from any other connected instrument. If one instrument goes into alarm, all connected units will go into alarm. The attendant will know exactly where the problem is because it’s visible on the instrument display. For example, the images to the left show the readings for two area monitors. The top monitor, within the confined space, is in alarm because of high H2S levels. The bottom monitor, which is placed near the attendant, shows a peer alarm indicating that there is high H2S in Area_001.

Having this information lets the attendant know that it's unsafe to enter the confined space without taking proper safety precautions and that the entrant should be evacuated. This is an example of how the equipment helps to bridge the gap for inexperienced or untrained workers. The area monitor loudly and clearly communicates the hazard so there is little need for interpretation or ambiguity. In addition to the gas reading and high-alarm icon, the attendant will know the difference between high alarms, low alarms, and maintenance reminders thanks to varying tones and different flashing colors that correspond to each alarm level. For example, flashing red means evacuate (high alarm), red and blue means approach with caution (low alarm), and blue means the instrument needs attention (low battery, calibration due, etc.) These communication mechanisms, combined with peer-to-peer wireless, help reduce false evacuations and better prepare workers for gas hazards around confined spaces.

Working in High-Noise, Low-Visibility Environments:

If you've ever worked around confined spaces, you've probably seen or heard about an incident involving missed alarms. Perhaps the attendant set the gas monitor on the ground and stepped away to sign paperwork or respond to a radio call. Because of noise from nearby machinery, the attendant completely failed to notice that the gas monitor went into high alarm, and he could not see it because it was lying on the ground. Powerful alarms and a highly visible design are two important features to consider when choosing an area monitor to perform confined space work.

When handheld monitors end up on the ground, tied to a railing, or left in other vulnerable positions, the pump and tube can be damaged or stop working. The rugged, upright design of an area monitor is beneficial because it's less likely to become damaged when left sitting in or near a confined space. The readings on handheld monitors are also difficult to see if the attendant is more than a couple of feet from the instrument. An area monitor with an extra-large display can be seen from a distance, which is helpful for attendants who are standing in another area or watching multiple monitors at once.

On the newest area monitors, alarm action messages can be programmed to correspond with rising gas levels within the confined space to provide early warning when conditions are starting to become unsafe. If the monitor is inside the space with the entrant, he would see "VENTILATE" instead of just "CO 35 PPM" and a flashing low-alarm icon. Likewise, for a high alarm inside the confined space, the entrant would see the gas reading of "H2S 20.0 PPM" and the alarm action message "EVACUATE." This gives the entrant and attendant extra time to respond appropriately, and with clear direction.

Monitoring Confined Spaces for an Extended Period:

When it comes to performing continuous monitoring of a confined space, wireless area monitors offer several advantages. The first benefit is remote monitoring capability. With peer-to-peer wireless, the conditions within a confined space can travel across the work site through "hops" and be seen by workers in nearby locations or even a safety manager up to 1 mile away. By having access to the gas readings within the confined space, the safety manager can easily maintain records and take action if an alarm event occurs.

The second benefit of using a peer-to-peer area monitor is instrument run time. Some area monitors can run off of a standard battery for several days on a single charge. Using an intrinsically safe external power supply will help to extend run time to over a week, even with an aspirated pump running and wireless enabled. By using gas monitors with extended run time, you can reduce how frequently instruments need to be swapped out and how frequently the work needs to be re-permitted.

Although handheld gas detectors have been the go-to for confined space applications, new area monitors with peer-to-peer wireless offer numerous safety advantages. Whether you are monitoring multiple confined spaces, working in high-noise, low-visibility environments, or monitoring a space for an extended period, it's time to evaluate what area monitoring options with peer-to-peer wireless are available to meet your needs. In the near future, look for ways that area monitors and personal monitors can work together to further ensure that we put an end to confined space and would-be rescuer fatalities.

This article originally appeared in the November 2016 issue of Occupational Health & Safety.