LDAR Programs Continue to Evolve

LDAR programs are shifting from reactive to proactive, evolving from mere compliance to actively seeking and repairing leaks to using the best available control technology and practices to prevent leaks from occurring in the first place. Mandated use of preventive technologies and programs could be next.

Leak detection and repair (LDAR) continues to be a topic of considerable interest to plant operators, government agencies and service providers. Three recent conferences,1 attracting between 100 and 1,000 attendees from these constituent groups, addressed a broad range of issues, including regulatory reform, performance testing, optical gas imaging, new regulations for oil and gas processors, analysis of leak and equipment data, and knowledge transfer to the next generation of LDAR managers.

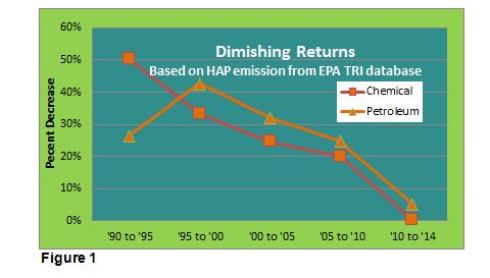

In terms of regulatory reform, we are approaching the point of diminishing returns with regard to reducing fugitive emissions (Figure 1). It appears that the energy expended and greenhouse gases emitted chasing down small leaks are greater than the environmental impact of the leaks themselves. The repetitive monitoring of the past 25 years makes little sense today as the percentage of leaking components decreases. This calls for a fresh look at regulatory regimens in light of current sealing and monitoring technologies.

In terms of regulatory reform, we are approaching the point of diminishing returns with regard to reducing fugitive emissions (Figure 1). It appears that the energy expended and greenhouse gases emitted chasing down small leaks are greater than the environmental impact of the leaks themselves. The repetitive monitoring of the past 25 years makes little sense today as the percentage of leaking components decreases. This calls for a fresh look at regulatory regimens in light of current sealing and monitoring technologies.

EPA's Next Generation Enforcement/Regulatory initiatives promote smarter regulations and permitting, as well as use of advanced monitoring techniques and electronic reporting. Plant operators are being forced to adopt best practices and technologies, while EPA moves to an electronic reporting system like the one it currently uses for its Toxic Release Inventory. The challenge is that state and local authorities use many different inventory systems. This will require interfaces to deal with these differences.

Driving down the percentage of leaking components are the good practices developed, implemented and enforced over the past 25 years. Testing specifications pioneered by Chevron and Shell paved the way for API-622, API-624 and ISO-15848 to pre-qualify valves and packings for low-emission performance. Mandating use of such pre-qualified components would call for revising if not entirely scrapping the requirement to use Method 21 (M21) to check and re-check seal performance. Indeed, many end users already require their suppliers to comply with these specifications, providing impetus for alignment of LDAR regulations.

Beyond Compliance

LDAR programs are shifting from reactive to proactive, evolving from mere compliance to actively seeking and repairing leaks to using the best available control technology and practices to prevent leaks from occurring in the first place. Mandated use of preventive technologies and programs could be next.

At the heart of prevention, whether compliance-driven or incentivized, are standard operating practices for properly and consistently installing and adjusting seals. The best technologies and practices are available and cost effective, and software systems can be used to track their low-emission performance.

At the inception of LDAR programs, leaks were defined at 10,000 ppmv or greater; now they are at 500 ppmv or less, typically 250 ppmv or even 100 ppmv, depending on location and consent orders. As noted, however, efforts to reduce fugitive emissions are having less and less of an environmental impact because there are fewer components exceeding defined leakage levels. So instead of measuring all components, a better approach may be to use alternative methods to find leaks. Examining the practices of other countries may be helpful in this regard.

For example, optical gas imaging is gaining increased attention as a viable alternative to Method 21. One user has reported a six-figure savings using this technology to measure difficult-to-monitor components. Interestingly, the savings were realized not by discovering and stopping leakage of costly media, but by eliminating the need to erect scaffolding to access these components.

Passive fenceline monitoring is now mandatory, but the specific location and magnitude of leaks can be detected through voluntary deployment of infrared (IR) gas cloud imaging or open-path Fourier transform IR (OP-FTIR) systems coupled with triangulation software. OGI equipment developers are now producing systems for quantifying emission concentrations, which could minimize or even obviate the use of organic vapor analyzers and Method 21.

Methane Reduction

Oil and gas wells and processing facilities are receiving heightened attention from regulators and environmentalists. Previously exempt from LDAR regulations, operators of these facilities are beginning to feel the effects of efforts to reduce methane emissions. These include Colorado regulations, federal regulations, the Paris agreements to achieve net zero emissions by the second half of the century, and pledges of support for these accords by the United States and Canada.

Refineries and chemical plants have been under EPA scrutiny since the early 1990s. Now, eliminating methane with its environmental impact equivalence of 25 times that of carbon dioxide has become a top priority.

Colorado led the way with regulations in 2014, followed in 2016 by federal regulations published in 40 CFR part 60, subpart OOOO, commonly referred to as Quad-O. These regulations apply to oil and gas upstream and midstream facilities, including oil and natural gas well sites, tank farms, gathering and boosting stations, gas processing plants, and pipeline compressor stations. These sites contain valves, pumps, compressors, thief hatches, vents, separators, and other components now subject to LDAR compliance.

With upwards of a million well heads in the United States, each with a relatively small number of regulated components, this poses a logistical challenge for operators, monitoring companies, low-emission component suppliers, and enforcement agencies.

Method 21 is giving way to optical gas monitoring as the preferred method of leak detection for these facilities. EPA inspection of natural gas processing plants has surfaced compliance issues similar to those of downstream refineries, namely failure to perform M21 properly, proper identification of regulated components, and sealing open-ended lines.

Injunctive actions in these instances include enhanced LDAR programs, more monitoring of tank thief hatches, and installation of control devices on distillation and reactor processes. Many of these actions are based on using the best available technology within the constraints of economic viability. Methane capture and mitigation activities are supporting businesses dedicated to providing the appropriate equipment, components, and services.

Focus on Leaking Components

LDAR programs involve the collection, organization, and maintenance of immense amounts of data. One LDAR service provider outlined a method for identifying components most likely to leak. By first gathering information on service conditions and equipment data, organizing it in a database, and tracking component performance, attention can be focused on what is usually a small number of leaking components contributing the most to total emissions. Adoption of such advanced practices could eliminate the need to monitor all components all the time.

With the aging and retirement of the U.S. workforce, the responsibility for LDAR programs falls upon those who are perhaps more energetic but less experienced. Training is necessary to facilitate this transition. Plant operators prefer to work with service providers that can assist with this training, as well as survey components, organize P&ID survey data, manage data and software, and provide sealing solutions.

The performance of valve stem seals continues to be an important factor in managing fugitive emissions. As noted, compliance with API-622 and API-624 has become a prerequisite for selling to the oil and gas industry. However, small cross-section packing for small valves is not being qualified to API-622, a situation receiving the attention of both valve and packing manufacturers.

While API-622 focuses on valve stem packings and seals, API-624 addresses overall valve performance, including gaskets, packings, and valve design. It should be noted that valve clearances and packing installation can make a seal qualified to API-622 perform differently than anticipated. As a result, it is expected this standard will be revised and, like API-624, will no longer permit packing adjustments.

Both API-622 and 624 stipulate leak levels of less than 100 ppmv, but most manufacturers are targeting 50 ppmv during development trials to provide a margin of safety for performance at user sites and third-party laboratories.

The LDAR conferences1 of 2016 have shown that regulations, best practices, and technologies are in a dynamic state. Regulators, plant operators, and technology providers are continuing to reduce fugitive emissions and keep them low. It is a quest that is both challenging and rewarding for those pursuing it.

References:

1. 4C HSE Conference, Feb. 22-25, 2016, Austin, TX; ISA LDAR Symposium, May 18-19, 2016, Denver, CO; Fugitive Emissions Summit Americas, June 13-14, 2016, Houston, TX.

About the Author

Jim Drago is the Principal Applications Engineer with Garlock Sealing Technologies, an EnPro Industries company that is located in Palmyra, N.Y.