Southwest Business Juggling Act: Droughts, Dust, and Water Regulations

By now, everyone has heard the term "new normal," which is short for "get used to it and change." That's the reality for the ongoing availability of water in states across the drought-stricken southwest United States. Despite a strong El Niño in 2015, current projections show a 33 percent chance of a water shortage in 2016 and a 75 percent chance in 2017.1 This could mean that the new normal for Southwest businesses includes restricted water volumes, higher costs, and future controls on the use of potable water for industrial purposes such as dust control.

Industries such as demolition, quarries, cement producers, landfills, and handlers of bulk materials of all kinds rely on water to mitigate fugitive dust emissions (airborne dust leaving the site perimeter) and to comply with federal, state, and municipal regulations. But the changes in available water supplies and regulations governing their use are impacting businesses in a number of ways.

As an example, California businesses have been required to cut water usage by 25 percent due to a 500-year low in snow pack in the Sierra Nevada Mountain Range, the main source of water to California. Some companies have found it challenging to strike a balance between the new water restrictions and stringent air quality standards, especially in large metropolitan areas.

However, California isn't the only state in the Southwest experiencing the effects of reduced water availability. Many utilities across the region are simply raising rates to inspire conservation in both residential and commercial sectors alike.

Circle of Blue, a water conservation advocacy organization, conducted a national rate survey and determined that the highest jumps in water prices between 2010 and 2015 occurred in the Southwest, with Santa Fe, N.M., having the highest monthly bills and Austin, Texas, recording the largest rate increase of 31 percent during that period.2

It seems the state most prepared for drought-like conditions is Arizona. According to Thomas Buschatzke, director of the Arizona Department of Water Resources, it is the only Colorado River state that has mandatory conservation programs.3 Nevertheless, the availability and cost of water aren't the only obstacles that Southwest businesses face in the future. More pressing -- and potentially more costly -- could be staying compliant with local, state, and federal air quality and industrial wastewater regulations.

Regulations

"Dust" is a generic term for minute solid particles, typically less than 500 microns in diameter. In bulk material handling, these particles are often created in a wide range of sizes, with larger, heavier particles tending to settle to the ground, while smaller, lighter solids may hang in the air indefinitely. Key to dust emission rules in most Southwest states is the difference in particle size between inhalable dust and respirable dust. The term "PM10" is standard across agencies and stands for "Particulate Matter" that is 10 microns (µm) in diameter (approximately the size of a human red blood cell). While particles larger than PM10 can be inhaled, they are usually trapped in the nose, throat, or upper respiratory tract.

A greater risk is posed by smaller particles. Respirable dust particles of PM10 and smaller can penetrate far into the lungs and migrate deep into the respiratory system. They are generally beyond the body's natural cleaning mechanisms (such as cilia and mucous membranes) and are likely to be retained. To put that in perspective, a human hair typically ranges from 50-75µm thick, so the most potentially hazardous dust particles are the ones too small to see.

Modern dust control needs have far outpaced common suppression technology such as fire hoses, large sprinklers and tanker spray trucks. To remain compliant, some businesses are switching to newer equipment designs, such as atomized mist units that utilize the concept of Variable Particle Sizing (VPS). The approach is based on matching the droplet size range to dust particle sizes to obtain maximum effectiveness.

Controlling Dust Particle By Particle

Most businesses that must adhere to air quality regulations either have a gravimetric dust monitor set permanently at the site perimeter or an inspector will carry a personal dust monitor on site visits. Samples of PM10 dust particles are taken upwind and downwind from the site to determine the amount of fugitive dust emitted vs. ambient dust normally in the air.

Field tests conducted by Dust Control Technology, based in Peoria, Ill., have found that in most bulk handling operations the majority of airborne dust is caused by disruption of material and that the common method of surface suppression (wetting the surface material) provides little benefit when front loaders or other large machinery is constantly disturbing it. Further, the saturation of material to prevent dust emissions uses a large volume of water and creates the potential for runoff.

When disrupted, dust particles under 200µm in size can linger in the air and travel long distances, even on moderate breezes. VPS dictates that for water droplets to optimize airborne dust suppression, the droplets must be roughly equal in size to maximize the collisions with airborne particles, mingling with the dust and pulling it to the ground.

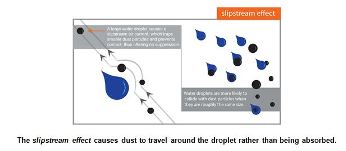

With conventional spray bars and sprinklers, the large water droplets create air currents around them as they fall, called the slipstream effect. Like the wind that travels around an airplane wing and gives it lift, large droplets cause the same effect on a much smaller scale. When the tiny particles encounter the larger droplets, they get caught in the slipstream, which causes them to travel around the droplet rather than be absorbed.

With conventional spray bars and sprinklers, the large water droplets create air currents around them as they fall, called the slipstream effect. Like the wind that travels around an airplane wing and gives it lift, large droplets cause the same effect on a much smaller scale. When the tiny particles encounter the larger droplets, they get caught in the slipstream, which causes them to travel around the droplet rather than be absorbed.

Due to the size of droplets they create -- as large as 10,000µm -- traditional dust suppression technologies have been largely ineffective at capturing airborne dust. In contrast, atomized mist droplets range in size between 50µm and 200µm, a far more effective range for capturing respirable dust particles. In fact, some manufacturers have engineered their equipment to produce droplets as small as 15µm, allowing their use for controlling targets as tiny as airborne odor vapor.

The Technology Gap

Fire hoses, large sprinklers, and tanker trucks rely heavily on surface suppression to mitigate dust and are inadequate for airborne dust control, yet they use a tremendous amount of water that leads to waste, runoff, and pooling. Instead, water-conscious operations are increasingly turning to atomized mist technology to deliver both surface suppression and airborne dust control. Developed in the last decade, the equipment delivers an engineered mist composed of millions of tiny droplets that can be thrown over long distances, using just a fraction of the water of existing techniques.

Hand-held fire hoses are a common dust management approach on many work sites. Hoses fitted with a 1.5-inch nozzle that draw water from municipal hydrants use about 100 gallons per minute (GPM), yielding droplets ranging in size from 200µm to 1000µm. They often require one or more workers to focus the sprays on problem areas, and they can create excessive runoff and mud. While the equipment cost is low, operation requires ongoing labor and wastes large volumes of water.

Also drawing from municipal hydrants, large sprinklers can use up to 500 GPM and create droplets 200µm to 10,000µm in size, which means they could fill two Olympic-sized swimming pools (1.2 million gallons) in just five 8-hour shifts. The benefit is that they can be tower mounted, cover wide areas, and require minimal labor to operate, but the amount of water runoff can make them unsuitable for many locations unless the site is designed with adequate containment.

Using upper and lower spray bars, tanker trucks have the benefit of mobility using a single driver, but the suppression range is limited to a few yards, with droplet sizes around 200µm to 500µm. The trucks only offer surface suppression in relatively flat areas where they can be driven and need to be filled periodically throughout the day, increasing labor costs. Moreover, they require a large amount of fuel to operate continuously.

Users of atomized mist technology can choose between a variety of different designs, including fan-driven units as well as low-turbulence models for applications in which a large airflow would be undesirable. Both approaches are able to eliminate the labor and minimize wasted water, with dust control performance that far exceeds conventional methods. Water is sent through specialized atomizing nozzles, which fracture the water into droplets approximately 50µm to 200µm in size. Large designs are available to cover as much as 280,000 square feet with a single machine.

The low-turbulence designs require only a suitable water supply, with no power needed. Fan-driven machines are typically manufactured in a standard 480V configuration, or users can specify voltages to suit their region. They can be direct-wired or plugged into a generator set. Some suppliers offer transportable units mounted on a road-worthy trailer, combining a workhorse electric dust suppression design with a diesel generator.

Wastewater Control

Runoff can be a problem when it has the potential to drain into waterways and aquifers, but even wastewater running into municipal sewage systems can have serious consequences due to conservation and treatment requirements in drought-affected areas. According to EPA, "The federal Clean Water Act requires that all municipal, industrial and commercial facilities that discharge wastewater or storm water directly from a point source (a discrete conveyance such as a pipe, ditch or channel) into a water of the United States (such as a lake, river or ocean) must obtain a National Pollutant Discharge Elimination System (NPDES) permit."4

This means businesses operating in areas with inadequate wastewater treatment may experience some increased regulation from excessive runoff and will certainly bear the cost of required equipment and infrastructure. Beyond the federal requirements, permits issued by local authorities that have mandated recycling or conservation can also have additional rules regarding wastewater. Most operators know the average type and levels of regulated material that they produce, but surprises can be disastrous. In the case of demolition and construction firms, if samples are taken and foreign substances not stated on the permit application are detected, work stoppage and fines can result. Even if the work site has runoff control, such as curbs, drainage ditches, or settling ponds, hydrophobic soil and cracking created by long periods of drought can cause large amounts of runoff to drain from the site into uncontrolled areas.

Community Relations

Air quality is a top issue for local communities, particularly in proximity to residential neighborhoods, businesses, and schools. Moreover, people passing commercial work sites may voice concerns over water usage, particularly if they are affected by conservation ordinances. Controlling dust while eliminating the use of high-pressure hydrants and reducing the amount of visible runoff can help reduce the number of complaints to local and state environmental authorities.

Methods that both conserve water and suppress dust carry multiple benefits beyond compliance. An example is in Texas, where a business can submit a Water Conservation Plan to the Texas Water Development Board and receive a subsidy based upon metered usage to offset increases.

By using improved technology that is environmentally friendly and conserves water, Southwest businesses and contractors can show a further commitment to the health and sustainability of the communities in which they operate. Additionally, some businesses may experience a reduction in overall operating costs, which is a "new normal" any business owner would be happy to live with.

Bibliography

1. Stone, Will. "Arizona Water Director: California Should Give Up More Water During Shortage," KJZZ interview, June 2, 2015. http://kjzz.org/content/147627/arizona-water-director-california-should-give-more-water-during-shortage

2. Staff, Circle of Blue, "Price of Water: 2010-2015," Traverse City, MI, 2015. http://www.circleofblue.org/waternews/wp-content/uploads/2015/04/WaterPricing2015graphs.pdf

3. Wilde, Troy, "Is AZ Facing Historic Water Restrictions Like CA?" Colorado Public News Service, Boulder, CO, April 2015. http://www.publicnewsservice.org/2015-04-02/water/is-az-facing-historic-water-restrictions-like-ca/a45480-1

4. Staff, "Water: Permitting (NPDES)," Environmental Protection Agency, Washington, D.C., Sept. 18, 2015. http://water.epa.gov/polwaste/npdes/

About the Author

Mike Lewis is a dust management specialist with Dust Control Technology. The company is located in Peoria, Ill., and has as its mission improving industrial air quality. Visit www.dustboss.com for information.