Treating Mine Tailings Runoff

Park City, Utah, hit pay dirt with an anaerobic biochemical reactor that removed more than 99 percent of cadmium and zinc from shallow groundwater.

- By Jeff Schoenbacher

- Jan 26, 2011

Before Park City, Utah hosted the Winter Olympics, it was known as one of the great silver mining towns. The mining district produced millions of ounces of silver as well as a substantial amount of mine tailing waste from the late 1860s to the 1970s. Because of this legacy, Park City has been remediating several areas ─ with state and federal oversight ─ since 1985.

One particularly challenging site within the city limits is a former mine tailings pond that was developed into a residential subdivision. Geographically, the development is located on the eastern side of the city at an elevation of 6,700 feet and is adjacent to Silver Creek, which spans the southern boundary of the development. A dewatering line conveys shallow groundwater from the tailings pond. The water from this line contains zinc and cadmium at levels that exceed water quality standards.

Park City Building Department started investigating passive treatment schemes such as biochemical reactors (also known as constructed wetlands) that take advantage of naturally occurring geochemical and biological processes to improve the water quality with minimal operation and maintenance requirements. The city teamed with the Missouri University of Science and Technology because research there focuses on quantifying removal mechanisms in bench-scale horizontal flow wetlands. The team effort began with building and operating a pilot test cell in June 2004, which eventually led to the construction of a full-scale, horizontal flow biochemical reactor late in 2008. The pilot unit ran for four years and showed significant removal of zinc and cadmium, with great variability in effluent concentration.

The full-scale biochemical reactor, built within a triangular parcel of land, had a simple design similar to that of a filter press, alternating layers of substrate with influent and effluent in a series of bands with one end acting as the supply (south) and the other as the uptake (north). The design included two layers of substrate separated by a gravel lens to eliminate any hydraulic short-circuiting. The theory behind the design is that water would channel through one layer of substrate and then directly flow through a second layer. Thus, the team designed the water flow path as gravel (influent), substrate, gravel (redistribute flow), substrate, and then gravel (effluent). The substrate make-up was similar to the pilot cell make-up with 50 percent Douglas-fir wood shavings or chips, 30 percent cow manure, and 20 percent clean limestone gravel that was 1-inch or smaller. For the inoculant, the team chose local cow manure from a dairy because the bacterium species is an efficient cellulose degrader. For dealing with head loss within the gravel, the team placed pipes in the bottom of the unit.

Ten-inch plastic delivery and collection pipes, located on each side of the biochemical reactor, were joined with four-inch perforated plastic pipes, which ran down the center of each gravel column extending from the inlet or outlet side. After flowing through the substrate lenses, the water eventually flows into a 36- by 36-foot, open-air pond on the southeast corner that acts as an additional buffer. The pond has a 10-inch collection pipe that travels through the five-foot clay-lined berm defining the east end of the biochemical reactor. The team lined the entire unit with six inches of clay to prevent the exchange of water to the underlying soils. The team placed an agricultural weir in the berm to adjust the water level in the pond; this placement prevents freezing of the outlet structure and provides an aeration mechanism for the treated water upon discharge from the biochemical reactor.

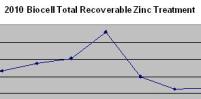

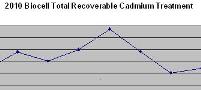

The biocell, which has been operating since October 2008, is treating shallow groundwater from the dewatering line below surface water quality standards (zinc 0.39 mg/L and cadmium 0.0008 mg/L) at a maximum flow rate of 70 gallons per minute (gpm). In the winter, the sulfate-reducing bacteria activity slows, lowering the flow rate to between 25 and 35 gpm. The following graphs illustrate the 2010 monthly treatment efficiency for dissolved zinc and cadmium after being treated by the biochemical reactor.

Biocell Total Recoverable Zinc Treatment. Click image for larger version.

Biocell Total Recoverable Cadmium Treatment. Click image for larger version.

During the first year of operation, 99 percent of the dissolved cadmium and 98 percent of the dissolved zinc were treated. In 2010, as the unit and the sulfate-reducing bacterium colonies matured, the performance improved with 99.8 percent of the dissolved cadmium fraction being treated and 99.3 percent of the dissolved zinc being treated.

Since the operation began, Park City has discovered the following facts:

- During peak spring runoff, the biocell can treat between about 60 and 70 gpm of the flow.

- The biocell can treat the dissolved fraction of zinc and cadmium to Silver Creek's total maximum daily load (TMDL) endpoint goal.

- In early winter when flows have not yet decreased, the sulfate-reducing bacteria are not as active, which slows treatment efficiency. However, to the systems benefit, winter flows also decrease.

Elimination of the cadmium and zinc pollutant load has benefited the Silver Creek watershed, and the biochemical reactor concept has been identified as a best management practice by Utah Department of Environmental Quality – Division of Water Quality within the federally approved TMDL.

The biochemical reactor has provided tangible results ─ improving water quality within the watershed with low maintenance and because it is gravity fed, the system requires no energy or chemical inputs.

The cost to build the unit was $400,220. Every spring, the city places approximately 60 cubic yards of new bark in areas where standing water is discovered in order to eliminate any aerobic influence. The city has some concern about the longevity of the unit because it is operating at such a high elevation. Nonetheless, two years into the operation of this unit, the city has achieved its goals.

The project was completed with assistance from U.S. Environmental Protection Agency Office of Research and Developed. An article on the subject, "Metal removal efficiency and ecotoxicological assessment of field-scale passive treatment biochemical reactors," can be reviewed in the Journal of Environmental Toxicology and Chemistry.

About the Author

Jeff Schoenbacher is the environmental coordinator at Park City, Utah.