Integrating Sustainability at Dow Chemical

- By L.K. Williams, EPonline

- Jul 21, 2010

You could say that Anne Wallin, Ph.D., has five years to meet Dow Chemical's current sustainable chemistry goal, but you would be missing the point.

Anne Wallin

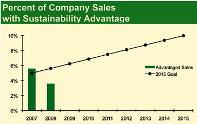

Wallin is director of Sustainable Chemistry for one of the largest chemical companies in the world (2009 sales were $45 billion for more than 5,000 products at 214 sites in 37 countries). Her work will not be finished in 2015, when the company's latest sustainability goals will mark their end. (But you can check the company's progress over the first quarter of 2010 [pdf]).

"Fundamentally, what we're really working toward is integrating sustainability into how work is done ─ capital, acquisition, how we go to market, how we talk to customers, how we move raw materials and products," Wallin explained. "The corporate function is relatively small. The point is to integrate this right where you are."

Or, right where the company's approximately 52,000 employees work. "In Dow, one of the things that creates alignment and drive and results is having metrics. Very clear metrics lets everyone align, from the top of the company to people who are running our facilities," Wallin explained. It's partly awareness education. Systematically and systemically, she "coaches" everyone on the payroll to think about what they are doing because each of them is a sustainability developer ─ even if, as she observed, "[s]ome of them don't know they're on the team yet."

But many of them do, and the outside world is taking notice. Last month, the company shared the Presidential Green Chemistry Challenge award with BASF for their Hydrogen Peroxide to Propylene Oxide (HPPO) process.

"[Propylene oxide] is not very visible," Wallin noted. "It’s a basic building block of the industry and yet [HPPO] is an incredible technological advance."

The process uses a ZSM-5 type zeolite catalyst to convert propylene to hydrogen peroxide. Titanium replaces several percent of the silicon of the zeolite in a tetrahedral coordination environment. At moderate temperature and pressure, the reaction occurs in the liquid phase in the presence of methanol. The low energy, fixed bed reactor process has high yields, according to Dow, and produces only propylene oxide (PO) and water. The company manufactures about 4 billion pounds of PO annually. As a chemical intermediate, it is used to make foam for seat cushions, flame retardants, modified starches, synthetic lubricants, oil field drilling chemicals, and textile surfactants.

This shared Presidential Green Chemistry Challenge award is the seventh for Dow since 1996, more than any other company or organization.

Also last month, NASDAQ added the company to its OMX Global Sustainability 50 Index for the first time. The index is made up of companies that have taken a leadership role in disclosing their carbon footprint, energy usage, water consumption, hazardous and non-hazardous waste, employee safety, workforce diversity, management composition and community investing.

Wallin has held her sustainability title and another for Life Cycle Assessment director since 2007, following stints as a process chemist in agricultural chemicals R&D, in roles for Environment, Health and Safety, and as a spokesperson in the Public Affairs office. She would argue that Dow has practiced sustainability, perhaps by another name, since the early 1900s when Herbert Henry Dow and George Westinghouse collaborated on the invention of co-generation. "That's still pretty state-of-the-art today," she commented, adding that the company helped to develop the fields of toxicology and industrial hygiene. "Sustainability is so integral that employees think these sorts of resources are available to every company," Wallin said.

Dow's 2015 Sustainability Goals focus on external issues such as society and climate change. After the company got its "house in order" under previous goals, it is now trying to help its customers and consumers work on their footprints, Wallin explained. For example, the company makes several building insulation products that she says probably save seven times more in greenhouse gas emissions than what Dow emits. Other "sustainable" products include more efficient electronics, electric transmission, and solar shingles.

Beyond products, the company is involved in change management. Company experts have provided testimony (pdf) to the U.S. Senate related to reforming the Toxic Substances and Control Act and frequently participate in committee work, such as an NSF International group that is trying to develop standards for green ingredient labels. Wallin also has served as a panel member at the latest American Chemical Society's Green Chemistry Institute (video).

Some people might wonder if Dow's green initiative was motivated, at least in part, by the need to overcome past mistakes, including dioxin contamination in its home state. Wallin responded: "We're making very long bets. We're making sure we are aligned with the scientific knowledge that we have now. We are a capital intensive company. Over 100 years we have legacy issues that we need to resolve, and we’re working with stakeholders on those." And then she added, "Doing it right the first time is going to be more competitive over the long haul."

Using a thoughtful approach, Dow is evaluating new chemistry carefully. The company is "looking" at nanotechnology, Wallin said, but also trying to determine its impacts on health and safety. "That's the challenge with science. Your knowledge is going to be finite. You will know more in 50 years. You have to take the knowledge you have. We have experts in every field of toxicology. They're following the literature, they're doing research. Science does not prove a negative. You have to manage uncertainty as you make decisions ─ take as holistic a look as you can. Some opportunities we're going to let pass by. That might sound difficult for a small company, but in a big company there's no shortage of great ideas and opportunities."

One of those great ideas was to set a high goal for worker safety. "We didn't make the target but we made incredible progress," Wallin said, adding that even small successes unleash creativity and energize and motivate employees. And that is what makes her job exciting. "I have a passion for this. Since graduate school, I wanted to work at the interface where everybody had a piece of the puzzle ─ the collaborative environment where we come up with solutions that are really going to be sustainable and stand the test of time."

(To find out more about the company's EH&S goals, visit http://www.dow.com/commitments/goals/protect.htm.)

Until the future proves yesterday's solution was sustainable, Dow will be trying to deliver results on its current goals and look forward to the next generation.

The Sustainable Chemical Index was 18.7 in 2007 and dropped to 18.1 in 2008. Dow attributes the decrease to a decrease in manufacturing efficiency that year, some of which was caused by the global economic crisis and hurricanes on the Gulf coast that closed plants down.

About the Author

L.K. Williams is the Environmental Group Editor of 1105 Media.