Case Study: MidCoast Water Manages GIS

- By Brendan Soustal

- Nov 05, 2009

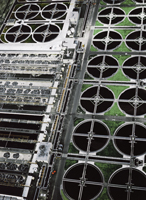

MidCoast Water’s treatment plant.

Less than a year ago, MidCoast Water (MCW) – a water and sewage services provider to the Manning and Great Lakes area of New South Wales – could not easily create consolidated reports or share information beyond its core records team.

Problem: Because the company delivers 11 billion liters of water per year to more than 35,000 households spread over 7,000 square kilometers, managing the needs of its large consumer base is both a complicated and complex mission. And while MCW used a geographical information system (GIS) to make this task easier, the program failed to live up to user expectations and the need to keep up with modern technology integration.

Struggling with a 10-year-old platform – and with little enthusiasm or commitment to upgrade – MCW faced a labor-ridden course with little flexibility or options to MCW’s end users. Six MCW departments – engineering, operational, construction, customer service, finance and GIS – used their own spatial management practices in a matrix of several technologies. Workers attempted to align management on service requests, work orders, distribution planning, financial applications, customer inquiries, and network maps for repairs.

The failed system made data sharing and project information distribution a lengthy and confusing process, cutting into the time meant for reporting on, scheduling and implementing projects, and resulting in a complete lack of integration between technologies.

Solution: When MCW made the decision to adopt Autodesk® Topobase™ software, department staff members saw that their new data integration center could characterize items spatially – project management systems, work orders, assets, customer information, environmental samples, lab results and any number of other business operations not traditionally geo-coded.

Immediately, workers and system administrators were able to recognize that the GIS arrangement, not the system itself, was the problem. Due to the age of the previous program, data quality rules and standards were failing to reflect where MCW was headed as an organization. This failure was turned on its head when the group fundamentally changed the data model, better representing items in the ground.

“MCW needed cutting-edge technology that could meet its requirements without disrupting business,” says Ian Cannington, industry manager, Utilities and Government for Autodesk Australia.

“MCW needed cutting-edge technology that could meet its requirements without disrupting business,” says Ian Cannington, industry manager, Utilities and Government for Autodesk Australia.

Working together, departments within the company determined that the final solution should provide an open and flexible portfolio of software – in this case, Autodesk’s Topobase software – that enabled MCW to effectively manage and protect its infrastructure.

The Work: MCW went to work right away using the intelligent design solution. Built on AutoCAD® Map 3D software, Autodesk MapGuide® software and accessing an Oracle database, Topobase configured easily with existing business systems. This feature was significant for MCW because Topobase was industry-built to support the needs of utility coding and data, the software contained a data model, business rules and multiple display models – all of which invoked simultaneous configuration.

MCW’s existing data was first migrated to the Topobase model. The database then worked to build a series of views and reports displaying the results in a single user interface. By closing the gap between GIS and computer aided design through industry-specific information management, Topobase provided better answers on geospatial questions. Industry teams now easily share information, dramatically reducing the need for data conversion processes and redundant entry procedure.

For MCW, the return on investment has been realized through business benefits, overhead reductions and a surging boost in user confidence.

Autodesk Topobase gives MCW the database and application tools to help maintain data accuracy and to provide a visual indicator of potential problems. In its maintenance planning process, workers can communicate changes more quickly and easily, helping to ensure that affected residents are aware of and prepared for any disruption in service.

MCW can now manage the maintenance of all its physical assets, including:

- scheduling and parts required;

- making informed decisions that impact the lifecycle of the sewer network as well as households using the company's services;

- allowing employees without programming or database expertise to use the system; and

- improving decision analysis.

In service for more than six months now, Topobase continues to aid with the representation of a changing physical environment by formulating an accurate graphical interface. MCW can analyze real world shifts and use data to plan for the future. While the current system is being maintained, strategic planning of new sewer and water schemes can be modeled and vetted before being inserted into the ground.

Now when addressing a repair, such as replacing an old section of a water utility pipe, engineers can draw up construction plans, zero in on the affected communities and quickly schedule a project. Once field teams replace the pipe, engineers add as-built information and document the project as complete, all within a central environment.

With new technologies and ongoing system improvements, MidCoast Water continues to provide safe, high-quality drinking water and responsibly managed waste treatment, meeting the current and future needs of its community.

About the Author

Brendan Soustal, GIS manager for MidCoast Water, a local government authority responsible for water and sewerage services on the Mid North Coast of Australia. He leads a specialist team of five and works in consultation with the organization’s Asset Management and Information Technology teams.

Joining MCW in 2002 as a land information systems graduate, Brendan has implemented a comprehensive program to improve the quality and quantity of asset information available to MidCoast Water personnel. This program has seen the development of innovative systems and substantial improvements in workplace efficiencies. It has also established new opportunities for data sharing within the industry.